Smooth Rides Ahead: Modernizing Vehicle Maintenance Strategies

Maintaining vehicles has come a long way from the time of grease-stained hands and manual check-ups. In today’s rapidly evolving technological landscape, vehicle maintenance has transformed into a sophisticated blend of data analytics, connectivity, and proactive strategies. This article dives deep into the various facets of modern vehicle maintenance, exploring how technology, data, and innovation are reshaping the way we keep our vehicles running smoothly.

The Importance of Vehicle Maintenance

Before delving into the modernization of vehicle maintenance, let’s revisit why maintenance matters. Vehicles are complex machines that require consistent care to perform at their best. Regular maintenance not only ensures optimal performance but also extends the lifespan of your vehicle and enhances safety on the road.

Evolving Landscape of Vehicle Maintenance

Gone are the days when vehicle maintenance relied solely on a reactive approach. The modern landscape embraces proactive strategies that leverage technology to anticipate and address issues before they escalate. This shift is essential, given the increasing complexity of vehicles and the demands of a fast-paced world.

The Traditional Approach to Vehicle Maintenance

Scheduled Maintenance: Pros and Cons

Historically, scheduled maintenance has been the norm, involving routine check-ups and replacements based on mileage or time intervals. While this approach has its merits in ensuring basic upkeep, it often lacks precision and may lead to unnecessary replacements.

Reactive Repairs: A Costly Gamble

The reactive approach involves fixing issues only when they arise. While this might seem cost-effective upfront, it can lead to higher expenses due to major breakdowns and reduced vehicle reliability. Reactive repairs also contribute to downtime and inconvenience.

Challenges of Traditional Maintenance Methods

Traditional maintenance methods struggle to cope with the complexity of modern vehicles. They often fail to identify underlying issues and may not consider individual driving habits and conditions. This can result in suboptimal performance and safety concerns.

Embracing Technology for Enhanced Maintenance

Role of Data Analytics in Maintenance

Data analytics is revolutionizing vehicle maintenance. By collecting and analyzing data from various vehicle sensors and systems, maintenance professionals can gain insights into performance trends, identify anomalies, and make informed decisions.

Telematics: Revolutionizing Vehicle Diagnostics

Telematics involves using advanced communication technology to transmit real-time data from vehicles to remote locations. This enables experts to monitor vehicle health, diagnose problems, and provide timely recommendations.

Predictive Maintenance Solutions

Predictive maintenance takes data analysis a step further. By employing machine learning algorithms, it predicts when components are likely to fail, allowing for proactive replacement. This minimizes downtime and reduces the chances of unexpected breakdowns.

Connected Vehicles and Maintenance Optimization

Modern vehicles are increasingly connected, allowing them to communicate with each other and with external systems. This connectivity opens doors for optimizing maintenance schedules, streamlining repairs, and enhancing overall efficiency.

IoT and its Impact on Vehicle Maintenance

Real-time Monitoring of Vehicle Health

The Internet of Things (IoT) enables real-time monitoring of vehicle health. Sensors embedded in different parts of the vehicle continuously transmit data, providing insights into engine performance, fuel efficiency, tire pressure, and more.

Remote Software Updates: Ensuring Optimal Performance

IoT also facilitates remote software updates. Manufacturers can send updates directly to vehicles, improving performance, addressing software bugs, and even adding new features. This reduces the need for physical visits to repair shops.

Shifting towards Proactive Maintenance

The combination of data analytics, telematics, and IoT is driving the shift towards proactive maintenance. Instead of waiting for a breakdown, maintenance can be planned based on actual vehicle condition, maximizing uptime and minimizing costs.

Understanding Proactive Maintenance Strategies

Condition-based Monitoring: Addressing Issues Early

Proactive maintenance strategies focus on condition-based monitoring. This involves tracking various parameters and setting thresholds. When a parameter deviates from the norm, maintenance personnel are alerted, allowing them to address the issue before it worsens.

Benefits of Proactive Maintenance Implementation

Implementing proactive maintenance offers numerous benefits. It reduces unexpected downtime, extends component lifespan, and enhances overall vehicle reliability. This approach also optimizes maintenance budgets by preventing unnecessary replacements.

AI and Machine Learning in Vehicle Maintenance

How AI Revolutionizes Maintenance Practices

Artificial Intelligence (AI) is a game-changer in maintenance. AI algorithms can analyze vast amounts of data to detect patterns that might elude human experts. This capability enables early issue detection and predictive insights.

Pattern Recognition for Early Issue Detection

AI’s pattern recognition capabilities excel in detecting subtle changes that indicate an impending issue. By analyzing historical data, AI algorithms can identify anomalies that signify potential problems.

Adaptive Learning for Improved Decision-Making

Machine learning algorithms adapt and learn from new data, continually improving their accuracy. This adaptive learning process enhances the precision of maintenance recommendations over time.

The Role of Big Data in Maintenance

Harnessing Big Data for Maintenance Insights

Big Data, generated from various sources, is a goldmine for maintenance insights. Analyzing this data provides a comprehensive view of vehicle performance, component wear and tear, and the effectiveness of maintenance strategies.

Data-driven Decision Making

Big Data empowers maintenance professionals to make informed decisions. By identifying trends and correlations, they can tailor maintenance approaches, prioritize critical components, and allocate resources more effectively.

Challenges of Managing and Analyzing Big Data

While Big Data offers immense potential, managing and analyzing it can be challenging. Data security, storage, and processing capabilities need to be robust to derive meaningful insights without compromising privacy.

The Rise of Electric Vehicles and Maintenance

Unique Maintenance Needs of Electric Vehicles

Electric vehicles (EVs) introduce new maintenance considerations. EVs have fewer moving parts, but their batteries require specialized care to ensure longevity and performance.

Battery Health Monitoring and Management

Maintaining optimal battery health is crucial for EV performance. Advanced systems monitor battery temperature, charge cycles, and overall health, allowing for timely maintenance and replacement.

Adapting Workshops for EV Maintenance

Repair shops need to adapt to cater to EVs. Technicians require training to handle EV-specific components and understand the unique challenges and maintenance requirements of electric vehicles.

Modern Tools for Maintenance Technicians

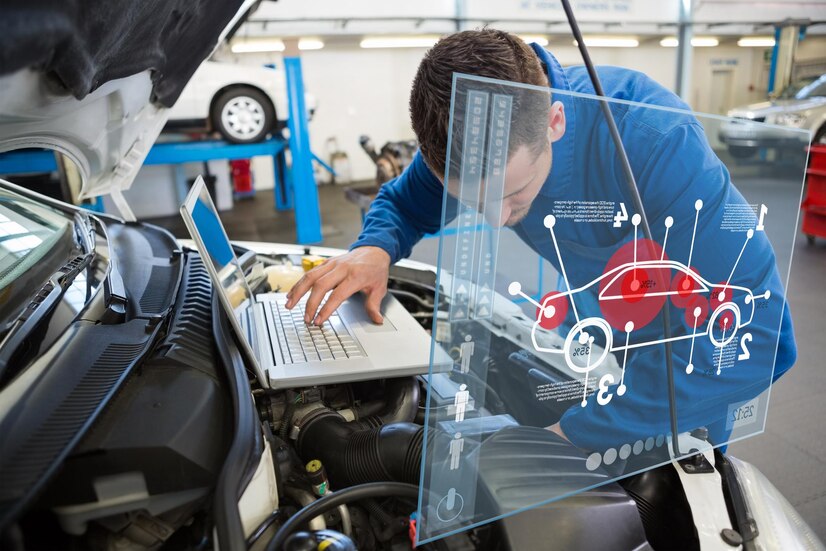

Advanced Diagnostics Tools

Modern maintenance technicians rely on advanced diagnostic tools to pinpoint issues accurately. These tools connect to vehicle systems, perform comprehensive scans, and provide detailed reports.

Augmented Reality Assistance in Repairs

Augmented reality (AR) is becoming a valuable tool in repairs. Technicians can wear AR glasses that overlay repair instructions on their field of view, improving efficiency and accuracy.

Robotics in Maintenance Operations

Robotic systems are also making their way into maintenance operations. Robots can perform repetitive tasks, such as inspections and minor repairs, with precision and consistency.

Ensuring Safety through Maintenance

The Link Between Maintenance and Vehicle Safety

Maintenance is intricately linked to vehicle safety. Neglected maintenance can lead to malfunctions that compromise safety, putting drivers, passengers, and pedestrians at risk.

Regulatory Compliance and Maintenance

Regulations often mandate specific maintenance schedules and safety checks. Adhering to these regulations is essential to ensure vehicles on the road meet the required safety standards.

Liability Implications of Neglected Maintenance

Neglecting maintenance can have legal implications. If an accident occurs due to poorly maintained components, liability issues may arise, leading to legal and financial consequences.

Sustainability and Eco-Friendly Maintenance

Eco-Conscious Maintenance Practices

As the world embraces sustainability, maintenance practices are also evolving. Eco-conscious approaches focus on reducing waste, conserving resources, and minimizing the environmental impact of maintenance activities.

Impact of Maintenance on Emissions

Maintenance plays a role in vehicle emissions. Well-maintained vehicles tend to have better fuel efficiency and emit fewer pollutants, contributing to cleaner air and a healthier environment.

Recycling and Disposing of Maintenance Waste

Proper disposal of maintenance waste is crucial. Oil, fluids, and parts must be recycled or disposed of responsibly to prevent environmental contamination.

Collaborative Ecosystems in Maintenance

OEM-User Partnerships for Efficient Maintenance

Original Equipment Manufacturers (OEMs) are collaborating with users to optimize maintenance. OEMs provide insights, updates, and recommendations based on real-time vehicle data.

Role of Dealerships in Modern Maintenance

Dealerships offer specialized expertise and genuine parts for vehicle maintenance. They are evolving into service centers that cater to both traditional and modern maintenance needs.

Third-party Maintenance Service Providers

Third-party providers offer alternatives to dealership services. These providers focus on quality maintenance at competitive prices, giving vehicle owners more options.

Training and Upskilling in Modern Maintenance

Evolving Skill Sets for Maintenance Technicians

Modern maintenance requires technicians to acquire new skills. They need to be proficient in data analysis, software diagnostics, and the operation of advanced tools and equipment.

Training Programs for Advanced Technologies

Training programs are essential to bridge the skills gap. Institutions are offering courses that teach technicians how to work with advanced technologies effectively.

Bridging the Skills Gap in Maintenance

The skills gap in maintenance is a challenge that needs to be addressed. By investing in training and upskilling, the industry can ensure a steady supply of qualified technicians.

Challenges in Implementing Modern Maintenance

Cost Considerations and ROI

Implementing modern maintenance strategies involves costs, including training, technology adoption, and equipment acquisition. However, the return on investment comes in the form of improved vehicle performance and reduced downtime.

Overcoming Technological Resistance

Resistance to new technology can be a hurdle. Technicians and organizations must understand the benefits of modernization and how it enhances their work rather than replacing it.

Integrating New Strategies with Existing Processes

Integrating modern strategies with existing processes requires careful planning. It’s essential to strike a balance that maximizes the benefits of new technology without disrupting day-to-day operations.

Cybersecurity in Vehicle Maintenance

Protecting Vehicle Systems from Cyber Threats

As vehicles become more connected, cybersecurity becomes paramount. Ensuring the security of vehicle systems and data is crucial to prevent unauthorized access and potential hacks.

Securing Data Exchange in Connected Vehicles

Secure data exchange is vital in connected vehicles. Encryption and secure communication protocols safeguard sensitive data transmitted between vehicles and external systems.

Balancing Connectivity and Security in Maintenance

Balancing connectivity and security is a challenge. While connectivity enhances maintenance practices, it also introduces potential vulnerabilities that need to be addressed.

Future Trends in Vehicle Maintenance

Autonomous Maintenance Processes

The future holds the promise of autonomous maintenance processes. AI-driven systems could analyze data, identify issues, and even perform minor maintenance tasks without human intervention.

Blockchain in Maintenance Records

Blockchain technology could revolutionize maintenance records. Immutable records of maintenance history could enhance transparency, reduce fraud, and improve resale value.

Role of Quantum Computing in Advanced Diagnostics

Quantum computing’s immense processing power could take diagnostics to the next level. Complex simulations and analyses could lead to more accurate issue detection and prediction.

Conclusion

Modernizing vehicle maintenance is not just a trend; it’s a necessity. As vehicles become more complex, interconnected, and environmentally conscious, maintenance strategies must evolve to keep pace. Leveraging data analytics, AI, IoT, and other advanced technologies allows us to take a proactive approach, ensuring smooth rides ahead for all vehicles on the road. By prioritizing safety, sustainability, and skill development, the automotive industry can empower reliable and efficient transportation for years to come.

FAQs (Frequently Asked Questions)

Why is vehicle maintenance important?

Vehicle maintenance is essential for optimal performance, extended lifespan, and safety. Neglected maintenance can lead to breakdowns and compromise vehicle reliability.

What is proactive maintenance?

Proactive maintenance involves using data and technology to anticipate and address issues before they become critical. It helps reduce downtime and enhance vehicle reliability.

How does AI impact vehicle maintenance?

AI revolutionizes maintenance by analyzing data, detecting patterns, and making predictions. It enhances early issue detection and improves decision-making.

Are electric vehicles harder to maintain?

Electric vehicles have unique maintenance needs, particularly related to battery health. However, they often have fewer moving parts, which can simplify certain aspects of maintenance.

How does cybersecurity relate to vehicle maintenance?

With connected vehicles, cybersecurity is crucial to protect vehicle systems and data from unauthorized access and potential hacks.